Broughton Lubricants are now part of Certas Lubricant Solutions, and because of this we now have access to a wide range of resources and support. This means we can improve and build upon the great level of customer service we already pride ourselves on, and can now offer a wider range of technical support and on-site services.

Application Specialists are on hand to provide customers with an effective fluid monitoring programme, and to help you get the most out of our lubricants.

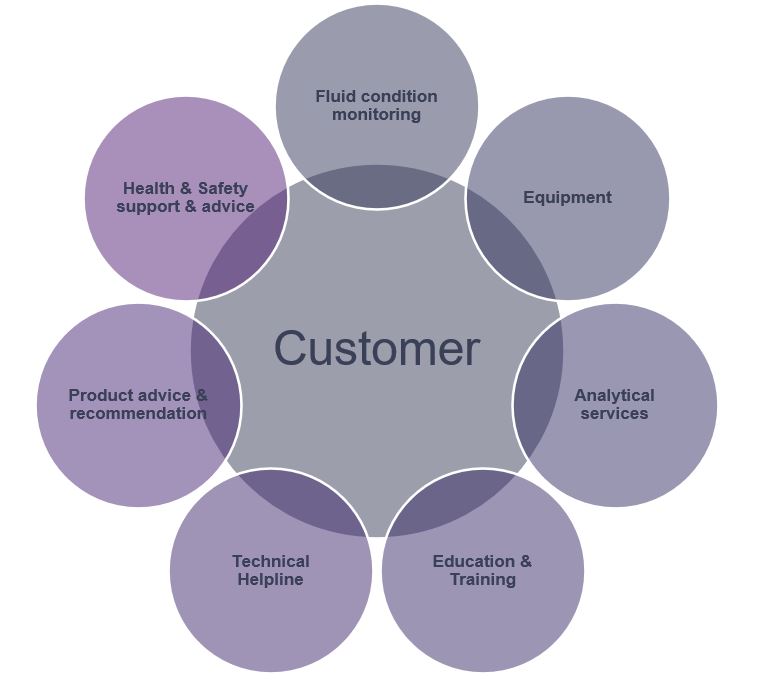

Their support includes:

- Advising the most effective product for your application.

- On-site fluid condition monitoring and problem solving.

- Training and advice on how to work safely with metalworking fluids.

- Helping you comply with health & safety legislation.

Monitoring will help you maximise performance and ensure you are meeting health & safety requirements. It can also help you reduce operating costs, improve production rates and increase machinery life.

Fluid Command...coming soon...

Being part of the Certas Energy Group provides us with access to many great new services, including; Fluid Command.

Fluid Command is the fluid monitoring programme that will help minimise unscheduled maintenance, increase coolant life and optimise performance, resulting in improved productivity and reduced machine downtime.

Choosing the correct metalworking fluid with the right balance of safety and performance is an important step in improving productivity and protecting employees. It is vital to appreciate that the composition of a metalworking fluid changes in use. Changes include both chemical deterioration and contamination, such as tramp oil, and also microbiological contamination.

It is therefore crucial to monitor metalworking fluids to maximise product performance and meet health and safety requirements. A full fluid condition monitoring programme is the best way to achieve this.

Any enquiries for Technical Services, or Fluid Command, please email - technical.celubes@certasenergy.co.uk

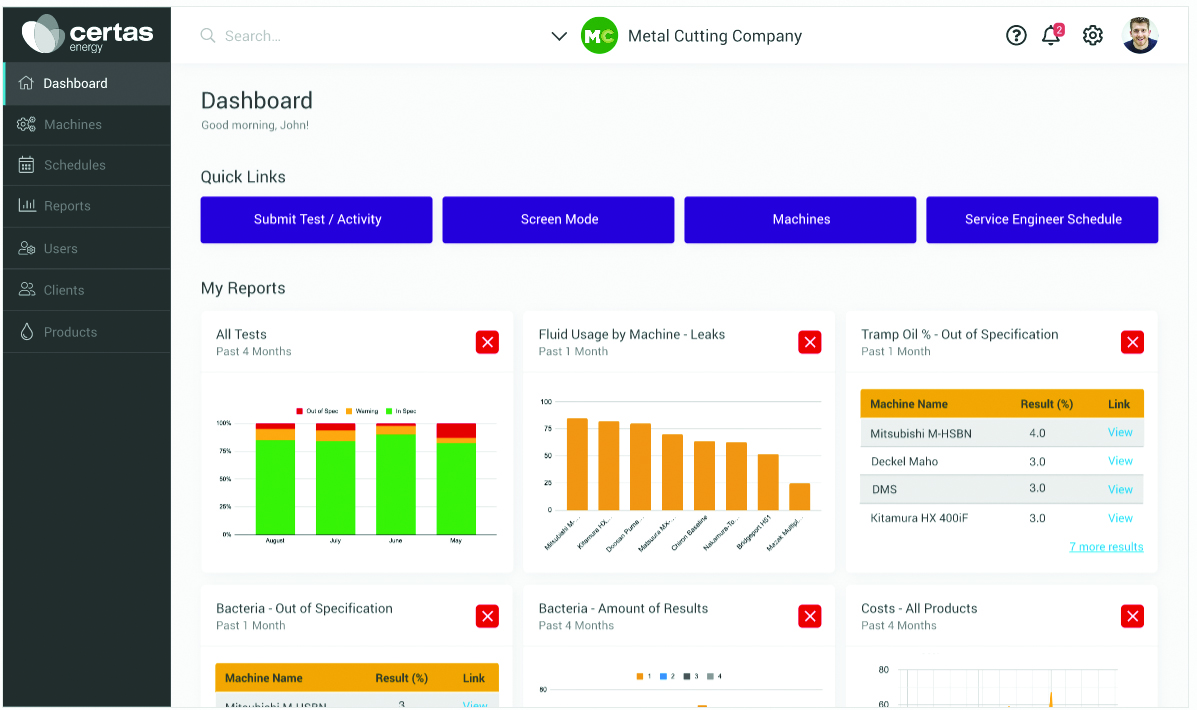

Take command of your metal workingfluids, no paperwork, no spreadsheets or missed maintenance schedules.

Machine reports and productivity insights at the click of a command button.

Cloud-based platform requires no additional hardware. Log-in with any digital device.

Complements your entire operations with fewer resources, HSE compliant, and reduced downtime.

Digitally savy and complete fluid management - your first steps into Industry 4.0.

View maintenance rotas, enter test data & view live data from a single CNC performance, to an entire production plant.

- View & manage your machine shop productivity.

- Testing and maintenance schedules.

- QR code scanning.

- Enter live test data at the machine.

- Easy access and instant results reporting.

- Easy to follow traffic light system to indicate machine performance.